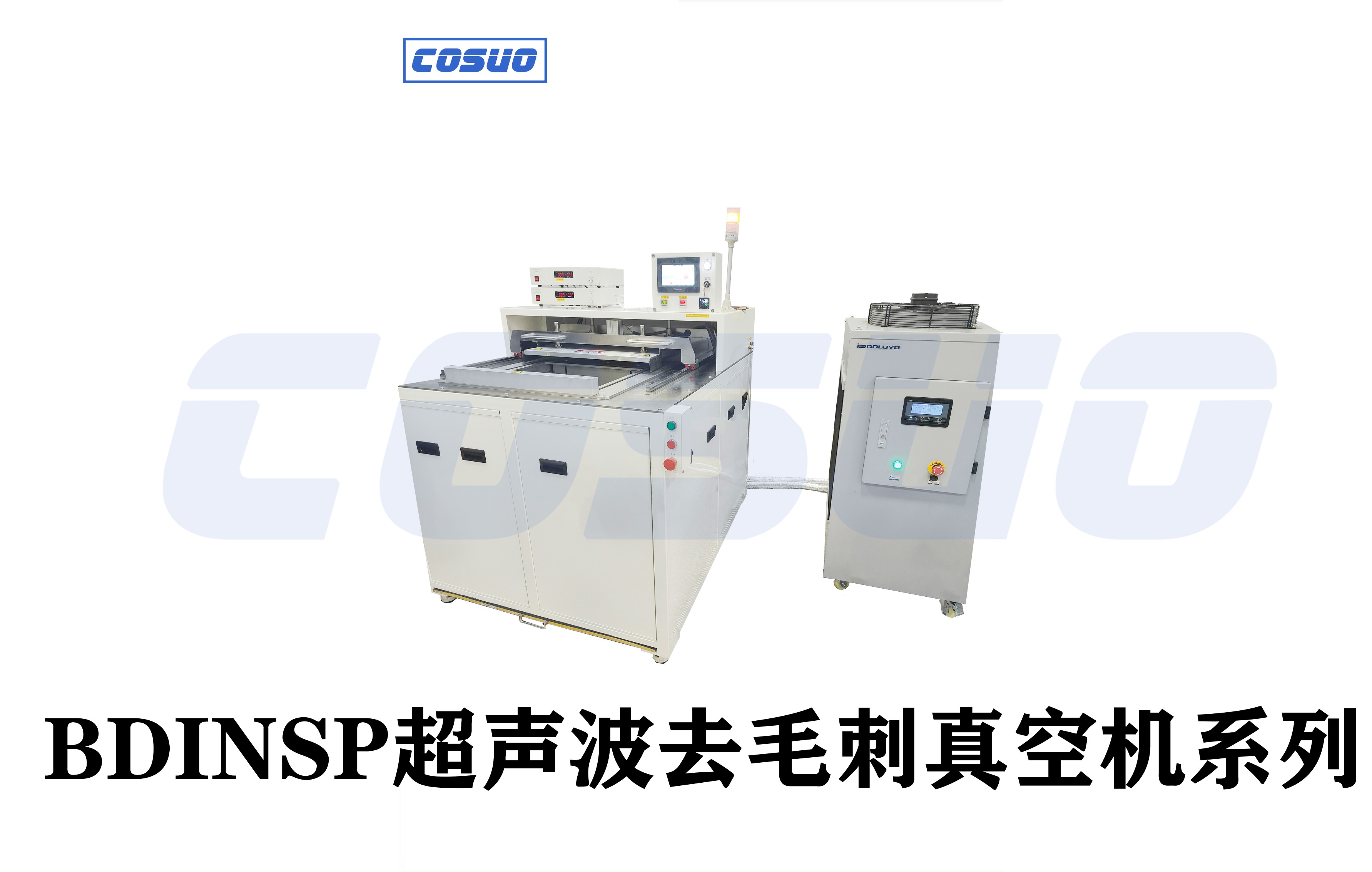

BDINSP Ultrasonic Deburring Vacuum Machine Series

scope of application

The vacuum machine is specially designed for deburring and cleaning of parts with complex structures such as inner cavity, blind hole and pipe; Deburring and cleaning of such parts has always been a technological problem in the precision manufacturing industry, and this model provides the best solution to this traditional technological problem.

The standard cleaning medium of the equipment is water, and the cleaning agent can also be used for special processes. It is mainly applicable to:

Metal precision machined parts, metal and plastic castings, glass, ceramics, casting sand removal, burr removal of molded parts in the mold, foil burr removal.

Equipment performance description

This equipment adopts Japan's most advanced wide area simultaneous multiple wave technology, and uses Japan's original vibration generator and vibration plate. The cavitation density generated in the process of ultrasonic emission in water is high and the uniformity is good, so as to achieve super strong and stable deburring ability. The ultrasonic output power density of this equipment reaches 2-4w/cm?, Far more than other domestic manufacturers.

The equipment has the following technical features:

1. the Japanese patent technology cavitation enhancement system technology is adopted to greatly increase the number of cavitation generated by ultrasonic in the solution, so that the ultrasonic cleaning intensity is greatly improved. 2 according to the characteristics of ultrasonic, the depth of cleaning liquid is effectively managed. Each liquid depth is calculated according to the theory, effectively eliminating the interface reflection of ultrasonic, which not only protects the vibrating plate, but also eliminates the end of ultrasonic local strength weakening caused by reflection. 3. equipped with multiple automatic circulation filtration system, the cleaning solution circulates continuously, ensuring the cleanliness of the cleaning solution and avoiding the deburring of parts and the secondary pollution after cleaning. 4. the cleaning medium used in this device can directly use ordinary tap water with low consumption and no pollution to the environment. 5 the device is equipped with cooling or heating devices according to different needs, and the temperature can be controlled according to the deburring requirements of different parts, so as to remove different types of burrs with maximum efficiency.

Operation method:

This equipment is equipped with a complete system, precise production, and extremely high level of intelligence. Under standard equipment conditions, except for manual operation of feeding and discharging (additional automatic conveying systems can be customized according to customer needs to cooperate with assembly line operations), other work steps are fully automated.

This device adopts touch screen operation, which is simple and direct; Automatic fault diagnosis and easy maintenance. Ordinary workers can work as long as they have received training and passed the technical personnel training of our company.

The main operation process is as follows:

1. Open the device, click the "Operation Preparation" button, and the device will start the automatic water addition program.

2. The equipment prepares for operation according to the preset time. When various indicators such as water temperature and dissolved oxygen content reach reasonable values, the system prompts that the preparation work is completed.

3. Prepare the workpiece basket and place the parts to be cleaned in batches. Place the workpiece basket on the hanging arm in the equipment cleaning tank, close the protective cover, and click to start the ultrasonic cleaning program.

During the ultrasonic deburring process, the removed burrs are automatically intercepted by the filter of the circulation system. According to the preset time, the device buzzer will sound when the cleaning is completed.

5. Open the protective cover, take out the workpiece basket, and prepare to place the next batch of workpieces.

6. According to different customer requirements, the configuration and settings of this device are also different. If the cleaned parts still need to undergo processes such as rust prevention and drying, our company can provide auxiliary devices together, and customers can also configure them themselves.